In October 2019, we announced the beginning of an academic collaboration on Tab-in-Tab with the Laboratoire de Pharmacie Galénique et de Biopharmacie de Bordeaux, a member of the Institut de Mécanique et d’Ingénierie.

Topic and challenges of the thesis

This collaboration is part of a doctoral thesis, under the supervision of Professor Pierre Tchoreloff and Doctor Vincent Mazel, with the following scientific orientation: “Mechanical resistance of pharmaceutical press coated tablets (tab-in-tab): characterization and link with material and process parameters”.

Aline Moulin, Pharmaceutical Development Director: “We are very proud to invest in research and development. This partnership allows us to further extend our expertise in the field of complex oral solid dosage forms“.

Léo Picart, PhD student: “It is important to understand the mechanical resistance of a pharmaceutical tablet. First, to preserve tablet integrity all along its life cycle after compression (handling, conveying, packaging, administration to the patient) and second, to understand the mechanical phenomena involved in the compression process. Process on which their production is based. This allows us to gain even more control over our process, and therefore to improve productivity and right first time. Tab-in-Tab tablets, because of their geometry (core inside a shell, both having different mechanical properties), have not been studied as much as single tablets. A detailed understanding of the links between process/material parameters and tablet mechanics (during and after compression) is therefore a very promising research topic.”

Partnership and collaboration between teams

This thesis is a project initiated by Skyepharma and partnered with I2M (Institute of Mechanics and Engineering), a laboratory of the University of Bordeaux, recognized worldwide for its expertise in the field of compression.

The advantage of this partnership is to benefit from both the company’s industrial experience and the laboratory’s scientific expertise. The research team, named “Galenic”, is co-directed by Pierre TCHORELOFF and Vincent MAZEL. It is specialized for many years in the study of pharmaceutical forms, including pharmaceutical tablets. The team therefore already has a wide knowledge of pharmaceutical compression, which is the basis of Léo Picart’s thesis.

Using the equipment at its disposal, the team can conduct a wide range of experiments allowing them to further their understanding of compression phenomena, and to develop breaking tests.

Today, given the results that the team has been able to generate, a reflection is underway to valorize these results by means of a patent application and scientific publications.

State-of-the-art equipment

The partnership between the Bordeaux University laboratory and the Skyepharma industrial site allows the team to benefit from state-of-the-art equipment for the scientific study of tablets: instrumented compression simulator (Styl’One Evolution), breaking tester, SEM (scanning electron microscopy), high-speed camera, and software environment: Abaqus (numerical simulation), VIC-2D (image correlation).

Image correlation results on tab-in-tab

Beyond the compression itself (and therefore the manufacturing process), it is very interesting in mechanics to study in detail the fracture of the tablets, as this allows to obtain valuable information on their resistance. We filmed the breakage of tablets produced on the Skyepharma site using a high-speed camera that we have in Bordeaux.

This software allows us to achieve a frequency of 1000 images per second in ultra HD allowing us to see the strain field on the surface of the tablet, even though it is very small and very fast movements. This allowed us to see the strains appearing long before the Tab-in-Tab broke. Images perfectly reflect the way the tablet is going to break.

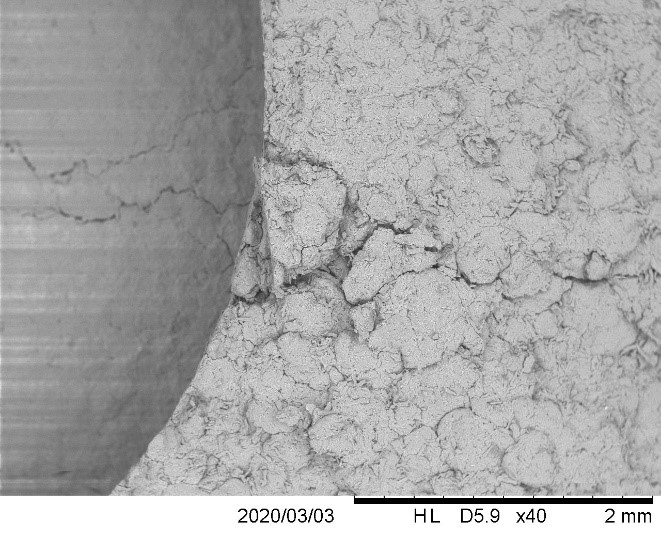

SEM image of the inside of a Tab-in-Tab after the breaking test

SEM (scanning electron microscopy) is an observation technique that involves bombarding a surface with electrons, and capturing the electrons that are re-emitted from the surface to form an image. It allows access to enlargements that are not possible with an optical microscope. We use it, for example, to observe cracks in the surface of tablets. In this picture, we can see a clear difference in density between two layers.

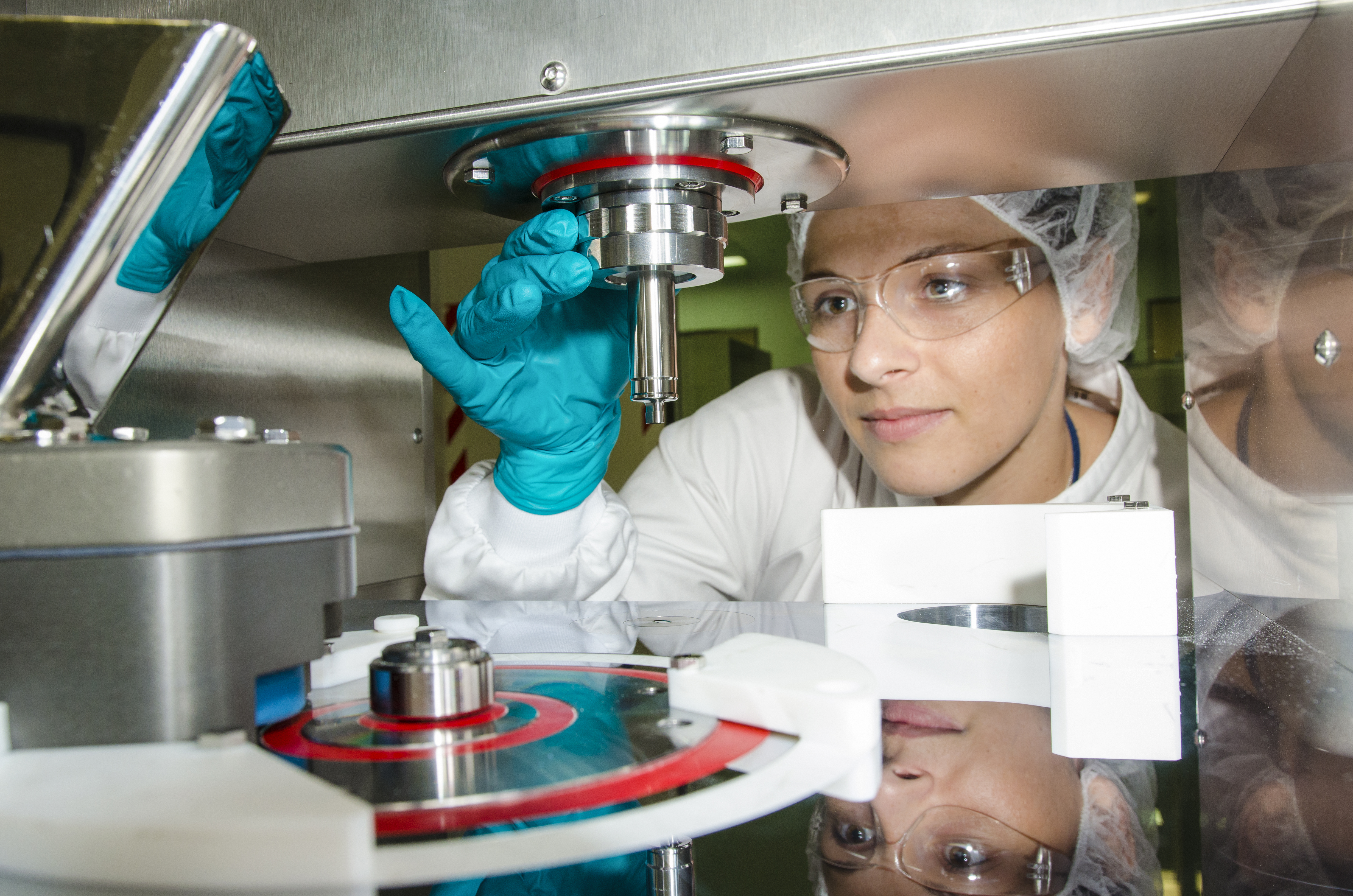

STYL’One Evolution (tab-in-tab tool) – On Skyepharma’s industrial site

The STYL’One Evolution is a compression simulator that allows us to carry out rapid and flexible prototyping tests to anticipate potential scale-up problems. The machine is equipped with specific tab-in-tab tools.

The galenic laboratory in Bordeaux is also equipped with this machine. It is essential for research in the field of compression because it allows to easily and precisely adjust the parameters in order to study their influence. The great interest of this simulator also lies in its multi-instrumentation: sensors allow access to axial and radial forces during compression, which are very important in the understanding of mechanical phenomena in compression.

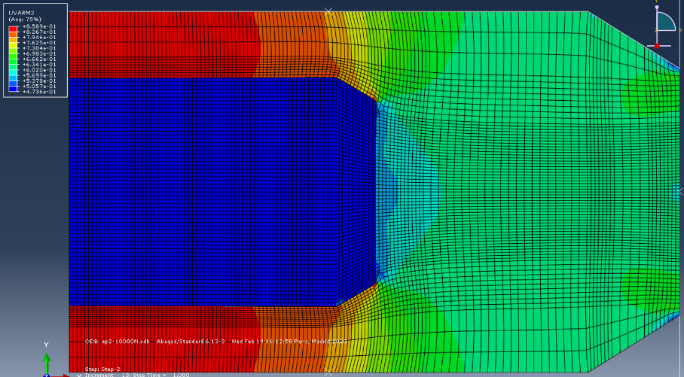

Numerical simulation result on tab-in-tab

In addition to the experimental compression manipulations, we are working on reproducing the experiments during simulation. The modelled tablet is a kind of “digital twin” of our experimental situation.

Pictures of a Tab-in-Tab model designed and printed in resin with the 3D printer (Stereolithography*) available at the Bordeaux laboratory.

*Principle of stereolithography: the support tray is immersed in liquid resin, and a laser illuminates certain areas very precisely in order to polymerize (harden) the resin layer by layer and create the part from top to bottom.

This tool is very useful for prototyping of components. During our manipulations, we need precise parts that aren’t always available on the market. Thanks to 3D printing we can design them on a CAD software and then print them in 3D immediately. This allows us to be more reactive if we need a complex part.

Pictures 1 and 4 are examples of parts that we have manufactured to equip the Tab-in-Tab module of the STYL’One (the original parts are dimensioned for 5mm or 6mm diameter cores, and those manufactured are for 8mm diameter cores). Photos 2 and 3 are mockups of tab-in-tab tablets that were designed to illustrate the structure of Tab-in-Tab.

ABOUT SKYEPHARMA

Skyepharma is a fully integrated, expert and agile CDMO specializing in complex oral forms. In this article, we aim to focus on the “D” expertise of our company. ¼ of our employees work in development. Our experience with controlled-release technologies (IR, SR, DR) is the basis of our expertise in complex forms. And we continue to strengthen our scientific expertise through research and development, and through collaboration like this one with the University of Bordeaux.

Learn more: early-stage development – controlled release technologies – tab-in-tab (Geoclock®) – About Skyepharma

Contact us: partnership@skyepharma.com – contact form