Quality by Design methodology (QbD)

Process Optimisation Tool

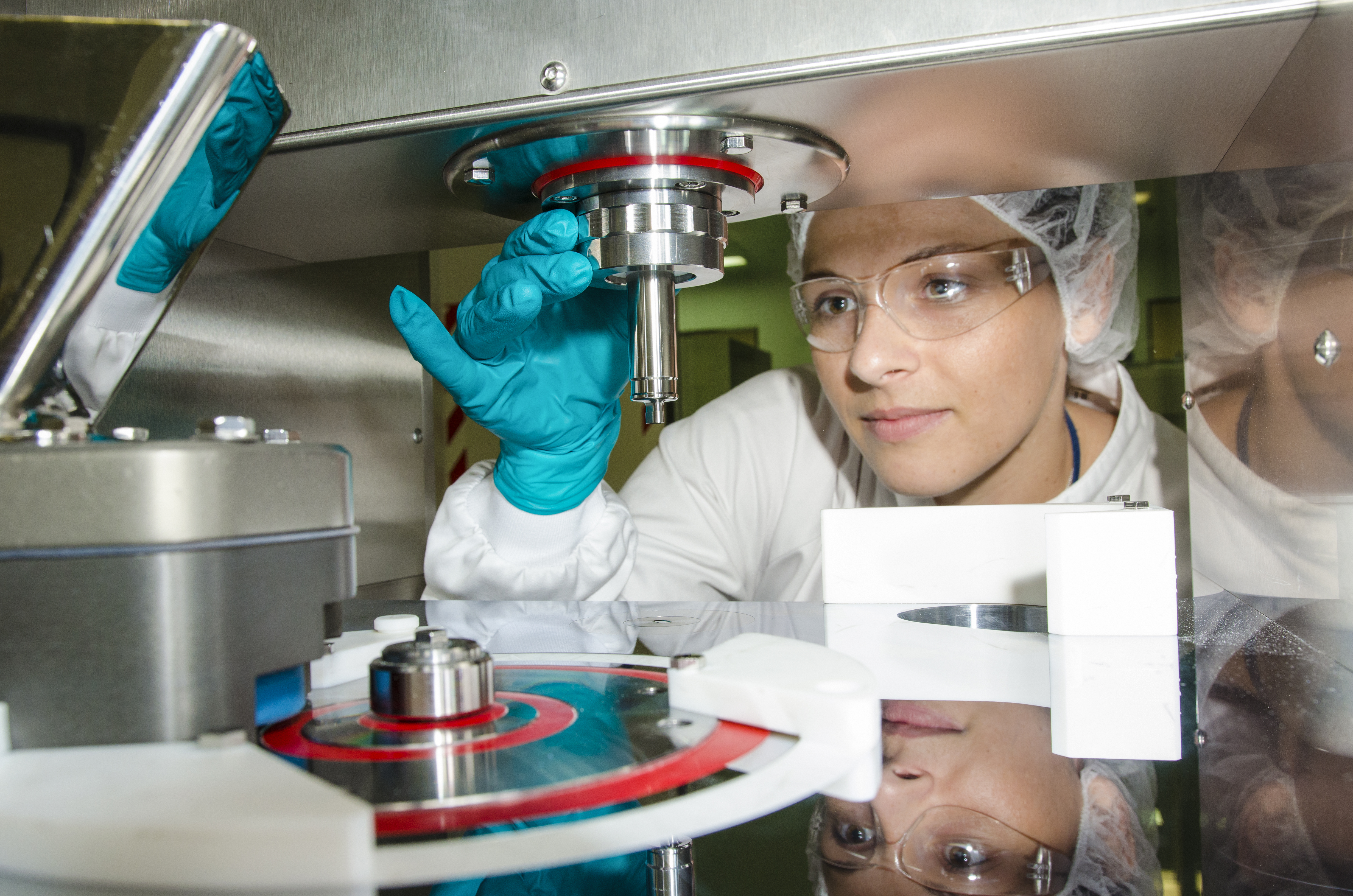

We apply Quality by Design approach for our customers’ projects, as part of our value proposal’s support services program.

Quality by Design is a development methodology which focuses on effective drug development. : it is a systematic and dynamic approach that assumes that quality is built in by design and is continuously improved. Quality by Design aims to better explore the characteristics of molecules, in order to better master the manufacturing process having identified the critical parameters.

Critical Parameters Identification

With critical parameters identification, we aim to more effectively explore the characteristics of molecules in order to better master the manufacturing processes

Efficiency design space with the STYL’One

We routinely use compaction simulators such as STYL’One Evolution to allow rapid QbD with small amount of raw materials & APIs.

By applying QbD , we secure the safe and effective supply of drugs to patients, whilst significantly improving our manufacturing quality performance.

Additional advantages include the reduction of finished product controls, shortening the time of batch release and reducing the number of out-of-specifications (OOS). From a regulatory perspective, the reduction of variation submissions in post-marketing phases is an important point in terms of resource management and cost.

Risk-free scale-up

We have expertise and strong experience in Quality by Design methodology, with the following tools :

- FMEA risk assesments (Failure Mode and Effect Analysis)

- FTA risk assesments (Fault Tree Analysis)

- DOE (Design of Equipment)

- Statistical data treatment with Minitab software